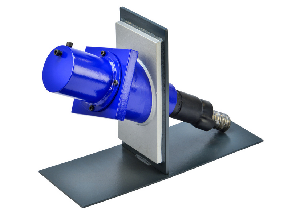

Grouted anchors - An innovative anchor that sets standards

Horizontal round steel tie rods generally represent the most cost-effective anchorage solution. However, if particular boundary conditions, e.g. structures nearby, unsuitable soils just below ground level or refurbishment work on existing structures, mean that horizontal anchors cannot be installed, then grouted anchors to DIN EN 14199 can be used.

An innovative anchor that sets standards.

Such anchors can be installed in changing subsoil conditions and in various lengths and at various angles. The anchor forces are carried via skin friction between the pile and the subsoil. In order to be able to assess the loadbearing behaviour of the piles, we recommend tension loading tests to DIN EN 14199 and “EA-Pfähle” (Recommendations on Piling, German Geotechnical Society). In contrast to round steel tie rods, it is not necessary to carry out any excavation work to install anchor piles. A hinge is to be preferred to fixity at the connection between sheet pile wall and head of anchor. Such a connection permits rotation, which compensates for deflection, settlement and installation conditions (see also EAU 2012).

An innovative anchor that sets standards.

Such anchors can be installed in changing subsoil conditions and in various lengths and at various angles. The anchor forces are carried via skin friction between the pile and the subsoil. In order to be able to assess the loadbearing behaviour of the piles, we recommend tension loading tests to DIN EN 14199 and “EA-Pfähle” (Recommendations on Piling, German Geotechnical Society). In contrast to round steel tie rods, it is not necessary to carry out any excavation work to install anchor piles. A hinge is to be preferred to fixity at the connection between sheet pile wall and head of anchor. Such a connection permits rotation, which compensates for deflection, settlement and installation conditions (see also EAU 2012).

Our grouted anchors can be fabricated with and without upset ends to DIN EN 1993-5 in lengths of up to 35 m. Furthermore, each pile can be extended to any length by welding or by using couplers.

Yield stresses of min. 355 to max. 590 N/mm² can be guaranteed depending on the grade of steel.

In addition, any type of wall connection is possible, e.g. upset thread, eye rod or T-head joint.

Advantages:

- High internal load-carrying capacity

- Low deformation, high robustness owing to high loadbearing reserves

- Easily adapted to suit tried-and-tested connection details (anchor plates, turnbuckles, couplers, eye rods, universal joints, etc.)

- For use in cohesive and friable soils

- The simplicity of the design according to the acknowledged standards of steel hydraulic engineering makes it easier for engineers to specify this system in their tenders.

- Designed for very high loads up to 7930 kN – up to 70% more than conventional piles.

- Suitable for use as tension and compression piles to DIN EN 14199.

- Low steel strain guarantees fast mobilisation of forces for small deformations.

- The surrounding grout constitutes an alkaline environment for corrosion protection over the full length – which saves work and costs.

Applications:

- Anchorages in port and specialist civil engineering

- Tension and compression foundation piles

- Anchorages for canal upgrades/extensions

Allowed design resistance to EC7-1, paragraph 7

You are reporting a typo in the following text:

Simply click the "Send typo report" button to complete the report. You can also include a comment.