Page 8 - ASF Katalog 2018 en

P. 8

2

ANCHORAGES

Thread rolling Advantages

All threads, especially upset thread sections, are rolled by us in our • Rolled threads have a high profile accuracy.

plant. We refrain from peeling the surface prior to rolling. That results in

no interruptions to the fibres, which leads to additional work hardening • Thread rolling is akin to a cold-forming operation.

of the surface. This increases the strength of the steel and the yield stress at

the root and flanks of the thread, which improves the

Any length of thread is possible on a solid bar, even over the entire bar concentric transfer of anchor forces via the thread.

on request. Both metric and inch threads can be supplied. The use of

inch threads and the associated coarser thread form results in simpler • The root and flanks of a rolled thread are particularly smooth

and faster progress on site. and therefore exhibit good durability in the case of dynamic

loads.

We guarantee high-quality threads and fast fabrication.

• In contrast to machined threads, the fibres in the steel are

not interrupted in rolled or hot-rolled threads.

• Nuts, couplers and turnbuckles for round steel tie rods with

rolled threads do not necessarily have to have a rolled thread

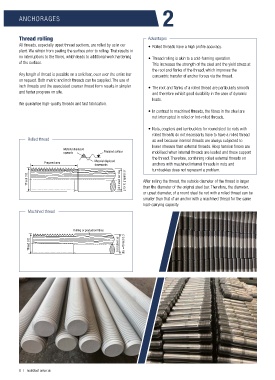

Rolled thread as well because internal threads are always subjected to

lower stresses than external threads. Hoop tension forces are

Material displaced

upwards Prepared surface mobilised when internal threads are loaded and these support

the thread. Therefore, combining rolled external threads on

Prepared area Material displaced anchors with machined internal threads in nuts and

downwards turnbuckles does not represent a problem.

Thread O.D. Solid steel bar dia. prior to preparation After rolling the thread, the outside diameter of the thread is larger

than the diameter of the original steel bar. Therefore, the diameter,

or upset diameter, of a round steel tie rod with a rolled thread can be

smaller than that of an anchor with a machined thread for the same

load-carrying capacity.

Machined thread

Rolling or production fibres

Thread O.D. Solid steel bar dia. = thread O.D.

8 | mail@asf-anker.de